Fensport GR Yaris ... The Build Diary 2021

Fensport GR Yaris build 2021

|

2021 the beginning...

Why?... Well the Yaris was an absolute dream car for us, finally a car where we could bring all of our ideas together, everything we had learned from our GT4X (4wd turbocharged) and our GT86R (rwd, wide and aero) and build a car which would have all the DNA of our previous Fensport cars :)

17th February 2021 - A huge thank you to Steven Eagell Peterborough for supplying the car!

|

It was soon run in and although we all loved the standard car, we knew we would need a whole lot more of everything in order to compete at the top level in the Toyota Sprint Series and Javelin Sprint Series so the car was on the ramp and the racing project started!

5th March 2021

Stripping the car starts with a corner weighting session, this is invaluable when it comes to deciding where to place parts later, as usual with a RHD car the passenger side rear corner is the lightest, so that is where we will place heavier items like water injection pumps and tanks.

|

10th March 2021 The car is now completely stripped and preparation for the roll cage begins with cutting out the seat rails, removal of sound deadening and any brackets which wont be used in the future. Engine, Gearbox & all glass is also now removed ready for roll cage welding.

|

12th March ... Time for a breather? No chance!

Whilst the car is away for its roll cage, work continues on all the parts left over. The engine is stripped, the direct injection is removed as we will be running an Ecumaster Ecu without Di capability. Work starts on lightening the already lightweight aluminium doors. The standard water pump is gutted and ported ready for an electric water pump conversion.

|

18th March .... The turbo is a big concern! Well its size is! The power level we will be chasing just will not flow through the small exhaust wheel so we are going with a Pulsar G25-660 and will make our own manifold, downpipe, exhaust etc.

|

22nd March ... The Pandem Rocket Bunny wide arch bodykit arrives safely from Japan and work begins on the tailgate and massive rear wing!

|

2nd April... At last the car returns and what a stunning job Custom Cages made of the cage :) We waste no time and get a seat in to measure up for the seat rails, wheels on and a test fit of the bodykit so we can get it away for painting asap.

|

3rd April... Test fitting of the Pandem kit. Wow we were keen to leave it like this!

After fitting the whole kit, right around the car and every panel fitted perfectly, every hole aligned up straight away, we were blown away with the quality. It may be expensive but the time saved on fitting makes it well worth it :)

|

6th April... Work continues on losing weight and the next bit to go was the boot floor, the GR Yaris has the battery in the boot normally so the panel is reinforced to take the weight. We saved 6.2kgs by cutting it out and later will replace with 1mm thick carbon fibre.

|

9th April... a 600 x 300 intercooler fitted and using a Summit & Swave front strut brace from an earlier model Yaris to provide both support and a crash beam, being aluminium and lightweight helped our choice! Also test fitting the dashboard before refitting the windscreen is much easier :)

|

10th April... Clutch time, we knew the standard dual mass flywheel and organic plate would not take the torque or heat that we would generate, there had already been a few failures in standard road cars. Helix Autosport came to the rescue and using our parts as patterns were able to manufacture a solution including a single mass flywheel conversion and race 6 paddle ceramic clutch plate with an uprated clutch cover. The complete kit also saved a massive 7kgs over standard. The gearbox does rattle though so not so good for a road car!

|

13th April... The intake manifold is taking shape, we had some flanges laser cut and our "Tom" was kept extremely busy with the alloy welding :)

|

Cusco's adjustable camber upper rear arms and adjustable toe control arms were fitted long with the pitching stopper to improve engine location.

|

18th April... Roll cage painting and FIA seat rails welded in

|

22nd April... Work starts on cutting the arches to allow for the big wheels and wide arch extensions

|

29th April... So much going on here! Starting at the front you can see the carbon shrouding to direct air through the intercooler and radiator. The intercooler is 600x300x75mm core with 3" alloy pipework. The intercooler is mounted to an extruded alloy bar (Thank you Summit). The radiator slam panel has been cut and modified to remove the bonnet catch and save weight.

We are using a larger diameter GT86 electric throttle body, leading in to our custom intake manifold. The clear plastic tubing is the start of our water methanol injection kit. The alloy pot above the gearbox is a custom made swirl pot to replace the factory plastic one.

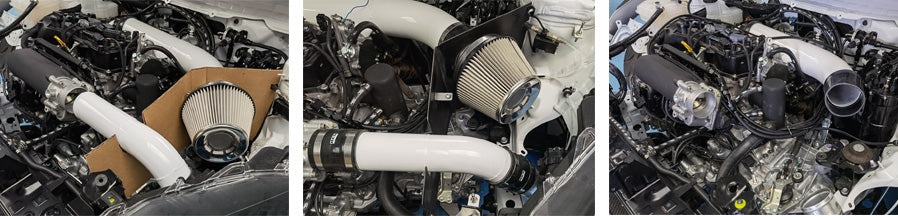

The intake pipe starts with a Blitz Sus air filter and leads to a 4" alloy intake which steps down to 3" just before the turbo inlet. Front wings are cut out and tabs have been made to hold a plastic liner.

|

|

30th April... Wrapping starts and building up the now painted Pandem bodykit, and yes we wrapped the carbon roof :)

|

4th May... Wiring! Tom the welder/fabricator turns out to be an expert at wiring, can bus systems and mapping too :) A complete wiring loom, Ecumaster EMU Black ecu, Ecumaster ADU 7" dash, Ecumaster PMU16 Power Distribution Module has been custom made to work with the standard car's fuel pump (which we use as a lift pump to a swirl pot with twin uprated pumps), cooling fan, power steering, rear diff control, electric water pump, and of course the engine control.

|

|

6th May... Plumbing and templating for carbon airbox, custom pipework and intake manifold with GT86 throttle body

|

7th May... Complete exhaust system is now made, starting from the custom exhaust manifold, G25-660 turbo, Turbosmart 45mm wastegate, downpipe, mid pipe, rear silencer all made in house.

|

8th May... The floorpans on the GR Yaris have a strengthening rib running down them, the standard car uses a polystyrene shaped foam under the carpet to make it flat. We made a removable alloy plate to take the standard GR mat, its always handy to be able to dry your feet on wet days! Also pictured is the carbon rear floor, removable for diff access.

|

9th May... Suspension time we have opted for the Australian made MCA Reds coilovers, MCA are the most successful suspension company in Australian Time Attack and had already been out testing the GR Yaris setup. We were honoured to be one of the first in the world with this great setup.

|

9th May... Brakes! Luckily the GR Yaris comes from the factory with very good brakes, we changed the Pads to Endless MX72, the brake lines were changed to Goodridge stainless lines, and the fluid to Castrol SRF. As the main use for the car is sprinting there was no need for any further upgrades.

You can also see the wheel spacer adaptors, they are being used temporarily so we can fit the wheels from our GT86R Race car. Once we know the correct fitment and offset etc we will get wheels made so we can run without the spacers :)

|

12th May... Interior is now finished, Ecumaster 7" dash & switch panel, Erl aquamist guage, custom carbon gear lever console, Corbeau Revolution X racing seat, Corbeau Ultima Pro 6 point harness. All safety equipment including roll cage is FIA 2021 specification.

|

18th May..... Some final touches and the car is ready to go, weight is 1157kgs with fuel and oil but not driver. More work will be done in the future to reduce weight.

|

More Fensport GR Yaris information